what is tensile impact test|impact testing equipment : manufacturer The tensile impact strength test was originally developed to overcome the deficiencies of flexural (both Izod and Charpy) impact test. All the test variables that have a high effect on the results, . Teams that have already been eliminated include Scotland, Bangladesh, Sri Lanka and Namibia. Cricket World Cup odds of all the teams are with recommended Sportsbook review, by the way. Ver mais

{plog:ftitle_list}

7 de dez. de 2023 · F# gives you simplicity and succinctness like Python with correctness, robustness and performance beyond C# or Java. F# is open source, cross-platform and free to use with professional tooling. F# is a JavaScript and .NET language for web, cloud, data-science, apps and more.

The tensile impact strength test was originally developed to overcome the deficiencies of flexural (both Izod and Charpy) impact test. All the test variables that have a high effect on the results, . Impact testing is a critical evaluation process that determines a material or product’s toughness, resilience, and durability when subjected to sudden forces or .

Impact tests are short-term tests which provide information on the failure behavior of materials or components subjected to rapid loading and at varying temperatures. The testing systems used . What is Impact Testing? Impact testing is a procedure that measures a material’s resistance to failure when subjected to high-rate loading. This method is used in multiple industries like automotive, .

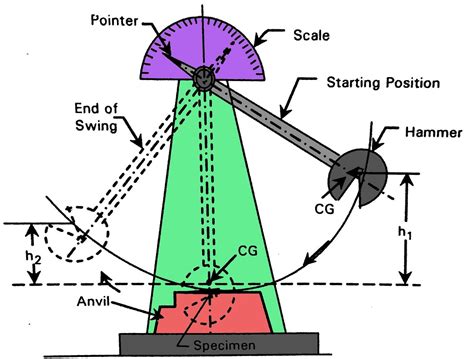

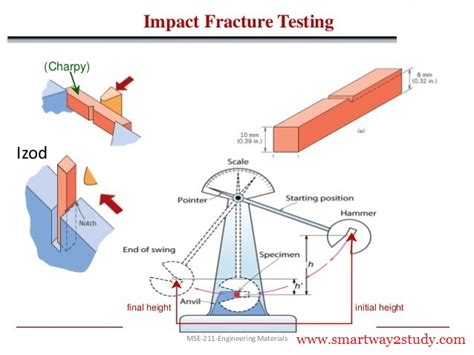

What is a Tensile pendulum impact test? A test method for determining energy required to fracture a specimen under shock tensile loading. Typically executed on a pendulum testing machine, the tensile impact strength test was originally .There are basically two types of impact tests: pendulum and drop weight. Izod, Charpy, and tensile impact are the most common of the pendulum type tests.

Tensile Impact Test: Tensile impact test refers to applying impact force at a specific sample position so that the sample is subjected to tensile force until it breaks. The test evaluates the material’s resistance to shock and its overall .The area beneath a stress/strain curve produced from a tensile test is a measure of the toughness of the test piece under slow loading conditions.

Tensile testing is a destructive test process that provides information about the tensile strength, yield strength, and ductility of the metallic material. It measures the force required to break a .

Tensile Impact Test: Tensile impact test refers to applying impact force at a specific sample position so that the sample is subjected to tensile force until it breaks. The test evaluates the material’s resistance to shock and its overall .The tensile impact strength test was originally developed to overcome the deficiencies of flexural (both Izod and Charpy) impact test. All the test variables that have a high effect on the results, such as notch sensitivity, toss factor and specimen thickness, are eliminated in the tensile impact test. This test, on the contrary of Izod and Critical in composite testing is alignment due to anisotropy, where material properties vary based on force direction.Aligning tests with the fiber orientation is vital for accurate results, especially in the aerospace industry . What is a tensile test?In the field of materials science and engineering, a tensile test is a widely used method to determine the mechanical properties of a material, specifically its response to tensile forces. It involves subjecting a specimen to an ever-increasing tensile load until it reaches its breaking point. By measuring the applied force and the resulting deformation .

Explore the crucial differences between impact vs tensile strength in polymers, and their implications for material selection in various applications. . During tensile testing, a sample is subjected to a controlled and increasing tensile force until it breaks, and the stress-strain curve obtained from this test provides valuable data on the .

squaretrade drop test pixel 2

what is impact testing

Impact test and tensile test are two common methods of mechanical testing that measure the resistance of materials to deformation and fracture. These tests are important for assessing the quality .The tensile test is a test method within mechanical materials testing, used for the determination of material characteristics.Depending on the material, the test is used in accordance with the respective industry standard for determination of the yield strength, tensile strength, strain at break and other material properties.. In the tensile test a material specimen is strained until it .

There are basically two types of impact tests: pendulum and drop weight. Izod, Charpy, and tensile impact are the most common of the pendulum type tests. What is impact testing machine? Impact testing machines evaluate an object's capacity to withstand high-rate loading and it is commonly used to determine the service life of a part or material. The tensile Testing method measures the force required to break a metallic, composite, or plastic specimen and the extent to which the specimen stretches or elongates to that breaking point. Tensile Test Procedure. A tensile specimen of standard dimensions machined from the metal is inserted in a tensile testing machine (shown in the below figure). The 50 kN capacity and the fully variable test speed of 0.2 to 51 mm/min make it possible to perform not only the CBR and Marshall tests, but many other applications as for instance Indirect Tensile test, Quick Triaxial tests, Unconfined and Uniaxial soil testing and, in general, all test to be performed under displacement control.

The Charpy impact test (Charpy V-notch test) is used to measure the toughness of materials under impact load at different temperatures! Test setup and test procedure. In the Charpy impact test, a notched specimen is abruptly subjected to bending stress. The specimen is usually 55 mm long and has a square cross-section with an edge length of 10 mm.

Impact Testing Impact testing ascertains the fracture characteristics of materials. It is used when laboratory tensile test results cannot be used to predict fracture behavior. One of the most common impact testing techniques is the Charpy method, designed to measure impact energy, or the toughness of the metal. Testing TechniqueWe will look at a very easy experiment that provides lots of information about the strength or the mechanical behavior of a material, called the tensile test. What is a Tensile Test? Tensile Test Procedure; Tensile Tests of Composites; Virtual Experiment Examples; What is a Tensile Test? The basic idea of a tensile test is to place a sample of .Impact testing has become firmly established in materials and components testing. The properties determined are part of basic material characterization. ZwickRoell has been delivering quality impact test equipment for years. . Other frequently used impact tests include the Izod test and impact tensile test. Izod tests, developed by ASTM, are .

Tensile Testing Machine Tensile Testing Machine is in its simplest form a frame, motor and load cell. The load cell is on a motorised arm and the load cell is connected to the material using a grip, the other end of the material is . How Charpy impact tests are performed. Specimen Preparation: A small, standardized specimen, usually a rectangular bar with a V-shaped notch machined on one side.The notch creates a stress concentration that promotes fracture when impacted. The test setup includes a pendulum hammer, a notched specimen holder, and a digital or analog .

The Charpy impact test is carried out in a 3-point flexure setup.The Charpy specimen is centered on the supports in the pendulum impact tester and rests against two anvils. In the case of notched specimens, the notch faces away .

The quantity usually measured is the energy absorbed in breaking the specimen in a single blow, as in the Charpy impact test and Izod impact test. Impact tests are also performed by subjecting specimens to multiple blows of increasing intensity, as in the drop ball impact test and the repeated blow impact test. Impact resilience and scleroscope .A pendulum impact testing machine is used to determine the impact strength or toughness of a material under impact loading by measuring the amount of energy the material is able to absorb. Knowing the energy absorption properties of a material is crucial for predicting how much plastic or permanent deformation the material can withstand before it fails.

types of impact testing

NextGen Material Testing offers a wide range of tensile testing equipment and the how-to knowledge for tensile test procedures. Home; Products. Special Offers. . Pendulum Charpy/Izod Impact Testing is a high strain-rate test to determine the amount of energy absorbed by a material during fracture.The Impact tester involves a pendulum of known .the samples in a refrigerator at 0ºC and then testing them using a tensile impact tester at room temperature would cause their temperature to rise by 4 to 9ºC within 20 to 25 seconds. 20 to 25 seconds was the average time needed to take a sample from the refrigerator, mount the test bar in the tensile impact tester and then perform the test. The ultimate tensile strength is the maximum tensile strength a metal has, and it typically is found after plastic deformation has begun to occur. The fracture tensile strength is the strength of the metal at the point of final failure. Testing Tensile Strength. A tensile testing machine is required to properly test the tensile strength of a .

ASTM E2248 – 18: Standard Test Method for Impact Testing of Miniaturized Charpy V-notch Specimens.; Ductile to brittle transition in impact testing. Carbon steel and low alloy steel are characterized by the fact that the fracture behavior changes as the temperature drops and the fracture type changes from ductility to brittleness.Filler metal manufacturers perform tensile testing on many of their products for several reasons. Like many end users, they may perform tensile testing to help monitor process quality. Tensile testing is also used by these manufacturers to determine and maintain product classifications and approvals from agencies such as the American Welding Society (AWS) or the American .In materials science, the Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain rate test which determines the amount of energy absorbed by a material during fracture.Absorbed energy is a measure of the material's notch toughness.It is widely used in industry, since it is easy to prepare and conduct and results can be obtained quickly and . The tensile test is performed by pulling on the welded joint until it fails under tension. The amount of force required to pull the welded joint apart is called the breaking strength or ultimate strength. . The Charpy impact test is used to determine the toughness of a welded joint and to compare the toughness of different welding processes .

Tensile Testing. Tensile testing is a fundamental mechanical strength test used to determine material properties such as stress, strain, and yield deformation. It involves subjecting a material to a force on opposite ends and pulling till it breaks. . Charpy Impact Test: This standard impact test can determine the energy required to fracture .

squaretrade drop test pixel 2 xl

webGame summary of the Ecuador vs. Costa Rica International Friendly game, final score 3-1, from June 20, 2023 on ESPN.

what is tensile impact test|impact testing equipment